Loading Virtual Tour...

Dorman’s story begins with the mass market automobile. The first moving assembly line was introduced in 1913, accelerating car manufacturing and making vehicles more affordable. Early cars offered people the newfound freedom of mobility. However, to maintain this freedom, people now needed to maintain their vehicles.

Dorman was founded on the belief that people should have the freedom to fix their vehicles. For over a century, we’ve provided countless products and services to help people do just that.

Today, we remain focused on driving new solutions, to help our partners grow their businesses, and help repair professionals and vehicle owners maintain their vehicles. That’s why our corporate tagline, and our promise to our customers, is Driving New Solutions.

Watching our Driving New Solutions anthem video to learn more about our story.

Everyone who works at Dorman is called a Contributor. We need every one, regardless of role and experience, to contribute to our success. That means everyone has a unique ability to make an impact on the business.

We encourage all our Contributors to bring their authentic selves to work. The freedom to pursue new ideas, to offer different perspectives, and to grow in your career are fundamental to working at Dorman.

At an innovative company like Dorman, it’s no wonder our values are IDEAS. Literally. That’s the acronym used to remember the principles by which we work and behave.

Organizations whose workforce composition reflects their customer base can better identify and understand their customers’ needs. As a result, our diverse and inclusive culture provides us with a competitive edge.

Dorman fully believes in the power and importance of fostering different perspectives in our contributors, customers, collaborators and communities. In fact, we believe this is a fundamental part of our Culture of Contribution. We want our contributors to feel continuously empowered to contribute their own unique ideas, talents and abilities.

To support our Contributors, promote professional growth, and give back to our various communities, we have a number of internal Contributor Resource Groups. These groups provides spaces for discussion and vehicles for planning and organizing events and initiatives.

Some examples of activities our CRGs have spearheaded include the Dorman Women’s Network 5K to benefit Jefferson Health’s mobile breast cancer screening unit, and the Dorman Veteran’s Network Gift Card Drive benefiting the America’s Mighty Warriors organization.

The Dorman Women’s Network was formed to provide a safe space for Contributors of all backgrounds to come together and share ideas in an inclusive environment. Its purpose is also to help drive professional growth and a measurable increase in diversity at all levels of the organization to evolve our Culture of Contribution. In 2020, this group raised money to support Women Against Abuse, a nonprofit based in Philadelphia that serves people experiencing intimate partner violence.

The Dorman Veteran’s Network is a community supporting the transition, hiring, retention and professional development of veterans at all levels. It is dedicated to fostering and advancing the inclusion of veterans in the workplace and within our communities. This group also support Operation Gratitude, a group that helps forge strong bonds between the military members and first responders through service projects and acts of gratitude.

The Dorman Multicultural Network is a resource group of culturally diverse professionals dedicated to support a diverse and inclusive work environment through fun and creative events and activities. The Multicultural Network’s goal is to provide an environment for contributors to share, learn, understand, appreciate, and celebrate all our diverse cultural backgrounds at Dorman.

While our products give people greater freedom to repair their vehicles, we believe the way we produce and distribute those products should not impede people’s freedom to live in a safe, healthy, beautiful world.

Likewise, our Culture of Contribution means both constantly contributing our best efforts and ideas to the success of the company, as well as contributing to our communities.

Learn more about our responsibility policies and view our fact sheet.

Advertising and social media play a pivotal role in driving Dorman’s brand growth. Through targeted campaigns and engaging content, we reach diverse audiences, including automotive professionals and DIY enthusiasts, showcasing the reliability and innovation of our solutions. Social media amplifies this impact by fostering direct interactions, building trust and encouraging user-generated content that highlights real-world success with our products.

Events and trade shows are essential to growing Dorman’s brand awareness and industry presence. These gatherings allow us to connect directly with professionals, enthusiasts and partners, showcasing our innovative automotive solutions and commitment to quality. By engaging face-to-face, we build trust, demonstrate expertise and gather valuable insights into market needs. The visibility and networking opportunities gained from participating in these events amplify our reach, solidify our position as an industry leader and open doors for future collaborations that drive growth.

Our award-winning content syndication and dynamic digital presence elevate our brand by delivering exceptional value to professionals and DIYers. We share high-quality, informative content shared across trusted platforms and our website, a central hub for product details, installation guides and industry insights. In doing so, customers are able make the decision to select Dorman products confidently. These strategies drive engagement, build brand trust and solidify Dorman’s position as a leader in innovative automotive repair solutions.

Media partnerships through TV spots, podcasts and radio expand Dorman’s reach and brand impact. With our goal of being the most sought-after brand in the aftermarket, we will continue to leverage these outlets and others to bring awareness to our brand and parts.

Through our partnership with TruckU, Dorman connects with truck, 4×4, and SUV enthusiasts by showcasing innovative repair and upgrade solutions. Hosted by Matt Steele and Bruno Massel, the show brings humor and hands-on expertise to everything from DIY maintenance to off-road performance upgrades. By demonstrating how Dorman products simplify projects and improve performance, TruckU strengthens our presence among passionate vehicle owners and reinforces our reputation for reliable, high-quality solutions.

With Two Guys Garage, Dorman partners with expert hosts Kevin Byrd and Willie B to bring automotive innovation and problem-solving to life. The show explores vehicle repair, customization, and restoration in a hands-on, approachable way. Featuring DIY tips, technical demonstrations, and insights into cutting-edge aftermarket solutions, this collaboration spotlights how Dorman products simplify repairs and enhance performance, building trust and engagement with car enthusiasts and professionals alike.

Dorman’s collaboration with CarFix celebrates creativity and expertise in the automotive world. With Bryan Fuller and Jeremy Bumpus tackling everything from everyday repairs to high-end restorations, the show highlights how Dorman solutions support both DIYers and professionals. This partnership strengthens our connection with car enthusiasts by showcasing innovative products that deliver quality and reliability for any project.

Dorman’s pairing with All Girls Garage showcases our innovative repair solutions through the expertise of Bogi and Faye, skilled technicians tackling everything from maintenance to engine swaps. By breaking down complex projects into DIY-friendly steps, this collaboration amplifies Dorman’s brand and connects with diverse audiences who trust our reliable, high-quality products.

The Under the Hood Show is one of America’s favorite car-talk podcasts with a nationwide audience of passionate automotive enthusiasts. Their format and extensive reach is ideal to showcase Dorman’s innovative solutions for the automotive aftermarket. By connecting with their loyal listener base, we strengthen brand recognition and highlight our commitment to empowering repair professionals and DIYers with real-world information about out high-quality, forward-thinking parts. Together, we’re part of conversations fueling automotive expertise and trust in Dorman.

We are proud to team up with The Car Doctor, hosted by Ron Ananian, a respected voice in the automotive industry. With its wide-reaching audience of repair professionals and vehicle owners, the show provides an ideal platform to showcase Dorman’s solutions. This partnership strengthens our connection to a passionate community, amplifying the stories behind our high-quality, problem-solving parts.

The C&C Auto Show is a trusted source of automotive advice with a loyal following across radio, podcasts and streaming platforms. Their commitment to educating and empowering car owners aligns perfectly with Dorman’s mission to deliver innovative aftermarket solutions. Through this partnership, we connect with a diverse audience of enthusiasts and professionals, further solidifying Dorman’s reputation as a leader in automotive repair.

As a partner of The Car Show, we reach a dedicated community of car enthusiasts who rely on expert insights to keep their vehicles on the road. The show’s rich history and broad audience provide a fantastic opportunity to highlight Dorman’s innovative aftermarket components, fostering trust and brand loyalty among professionals and DIYers alike. Together, we build confidence in automotive repair.

Our investment in motorsports sponsorships has helped solidify our brand as one of the preeminent aftermarket suppliers. Being present at events like these keeps our brand top of mind with our customers.

Dorman Products is proud to partner with Spire Motorsports, a rising force in NASCAR that exemplifies innovation, perseverance, and competitive excellence. Through this sponsorship, Dorman aligns with the high-speed world of stock car racing, connecting with millions of passionate fans and automotive enthusiasts. Spire’s commitment to pushing boundaries on and off the track reflects Dorman’s dedication to delivering innovative aftermarket solutions that empower repair professionals and DIYers alike. Together, we’re driving performance, reliability and a shared passion for all things automotive.

As a multi-time NHRA champion, Ron Capps exemplifies excellence and precision. Dorman is proud to support his team as they continue to push boundaries in the fast-paced world of drag racing, showcasing the durability and innovation that our products deliver.

In the high-octane world of Formula Drift, where control and adaptability to changing conditions hang in balance, Rich Whiteman and Freedom Motorsportz represent the cutting edge of performance. Partnering with them allows Dorman to reach an audience that values creativity and precision in every turn.

As a trailblazer in Touring Cars, Sally McNulty inspires with her tenacity and skill. Dorman is proud to stand behind her efforts, connecting with grassroots racing fans and showcasing our commitment to automotive performance.

By partnering with trusted industry voices, Dorman connects with enthusiasts, professionals, and DIYers who rely on our products. These collaborations highlight our high-quality solutions while fostering a vibrant community and building trust across the automotive industry.

Our team of field analysts regularly visits shops and garages throughout North America to learn what issues they are encountering.

Are they starting to see a lot of the same vehicles with the same failures? Is a certain part design making repair difficult? Is there a particularly failure-prone component that the dealership doesn’t sell individually, which would save a lot of time and money if it were available?

These experts bring that intelligence back to our product teams to build our pipeline of solutions.

Online communities and advanced data analysis tools have allowed our ideation teams to cast a much wider net.

Our product experts are now constantly examining data from a number of different sources to identify where there are opportunities to give people better solutions. We are always looking for patterns of problems, building forecasts of future failures, and soliciting feedback from thousands of professionals.

We currently have more than a dozen different sources of useful data we pull from, and we are uncovering new sources all the time.

Because we’ve been doing this for decades, we’ve earned a reputation for solving our industry’s problems.

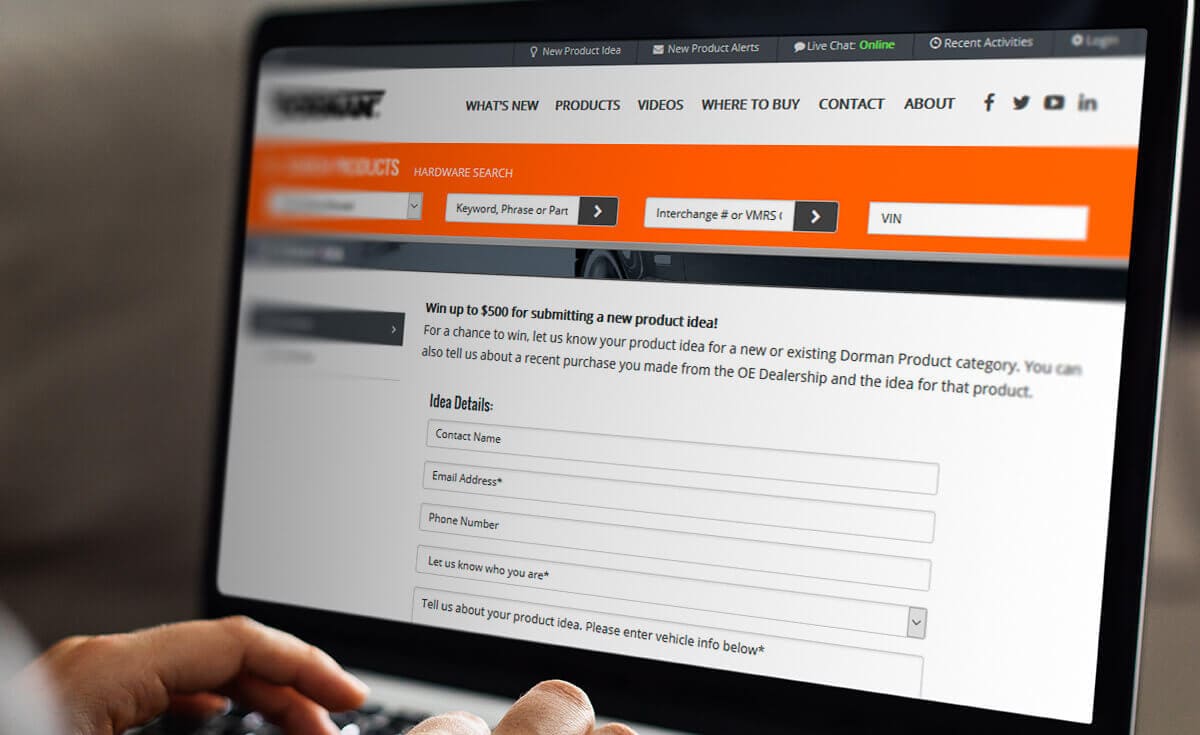

That’s why there are people who approach us with ideas for new products every day, both through our website and our Technical Support Team.

(P.S. Have an idea? Submit it here!)

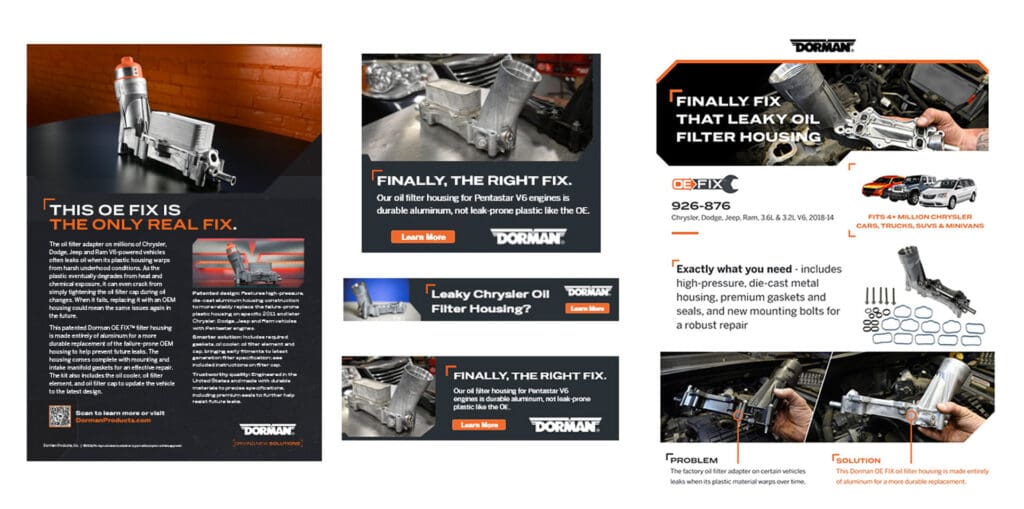

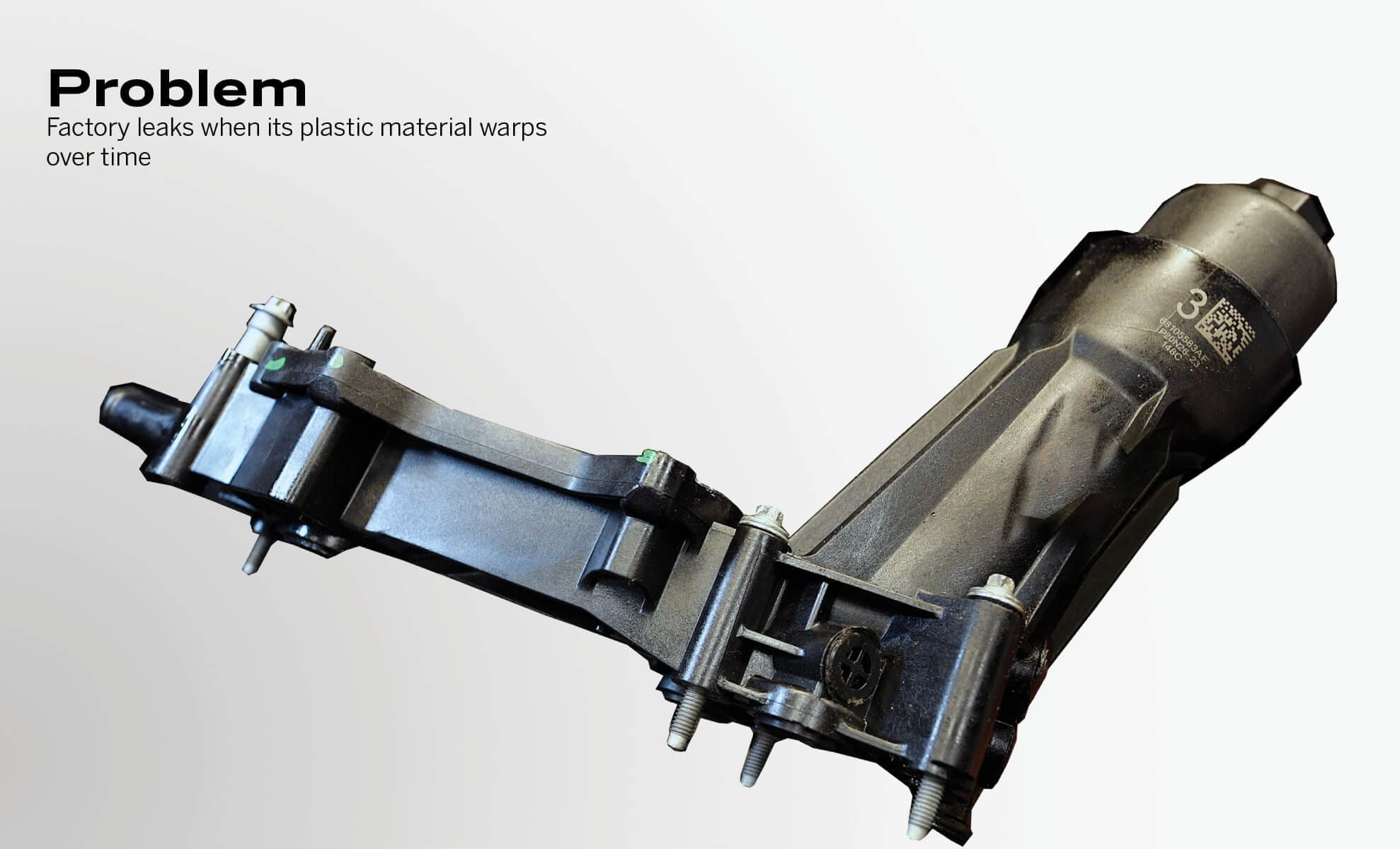

In the course of gathering and analyzing new ideas, we often find a critical flaw in the original equipment that causes a part or component to fail prematurely in certain conditions.

Or, we find people would like to repair a vehicle in a fast, cost-effective way, but the original manufacturer doesn’t sell the specific parts they need.

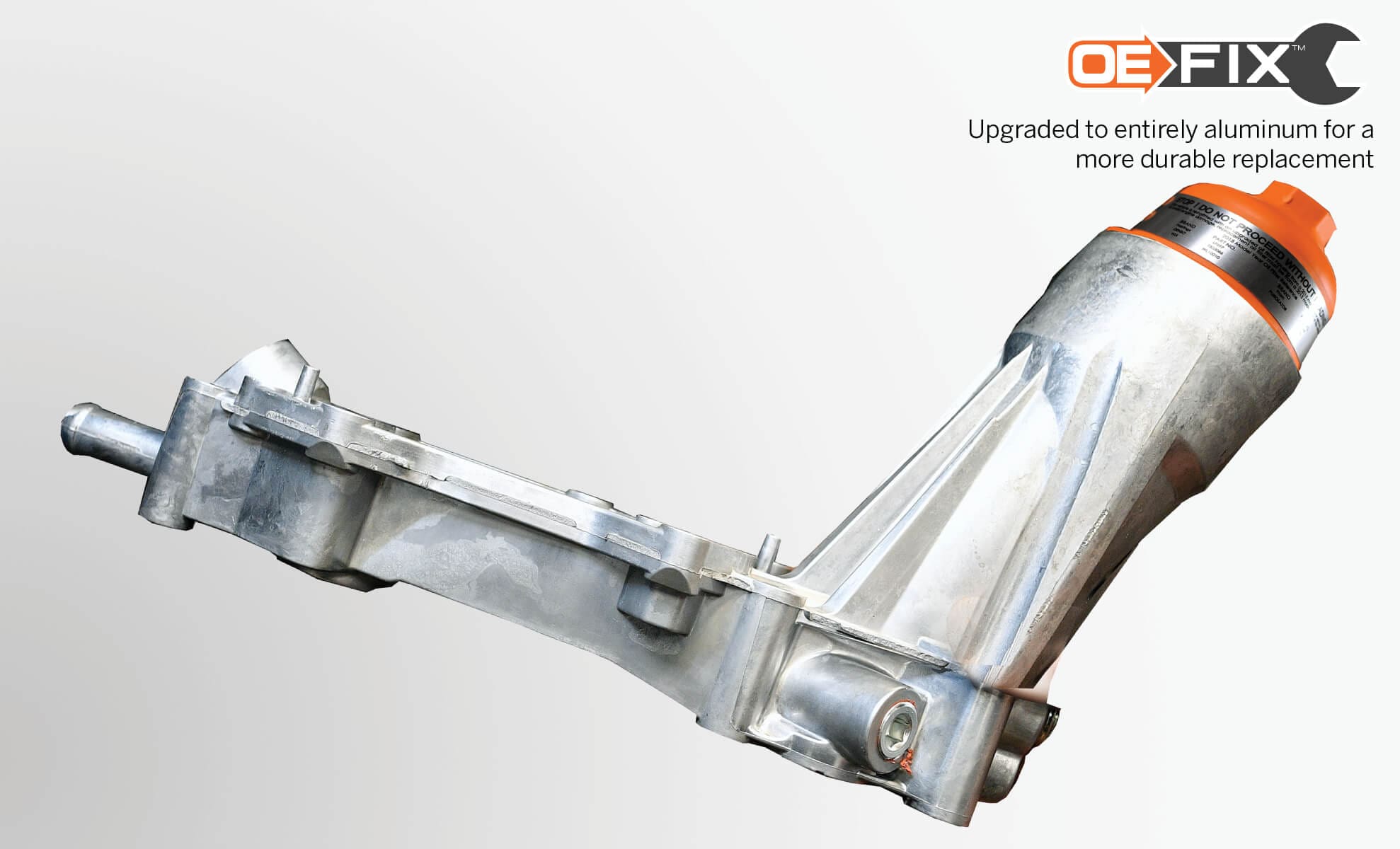

Whenever we develop a solution to these problems, we call it an OE FIX. An OE FIX is simply a repair solution you can’t get from the OEM.

One type of OE FIX is a part that Dorman experts redesigned to save installation time or improve reliability.

When designing an original part, OEMs aren’t always incentivized to consider the needs of repair professionals or vehicle owners first. Manufacturer-centric concerns, like weight reduction and ease of factory assembly, sometimes lead to products that are failure-prone and frustrating to replace.

We put installers’ and owners’ concerns first, changing the design, components or materials of parts to reduce the likelihood of future failures and simplify replacement.

Another type of OE FIX is a part that you simply can’t buy from the OEM.

When it comes to supplying replacement parts, OEMs aren’t always customer friendly. Frequently, you have to buy an entire part assembly just to fix a small broken piece, or you have to separately buy and assemble multiple parts.

We routinely develop direct replacements for the most failure-prone components, often enabling you to replace only the failed piece, not the whole assembly. We also pre-assemble certain products to save installation time.

Often, the innovation is simply making a product available in the aftermarket.

When repair shops or vehicle owners can only buy replacement parts from the original vehicle manufacturer, they’re often faced with inconvenience and higher costs.

That’s why Dorman constantly introduces new replacements parts to the automotive aftermarket. These parts are designed to function like the originals for specific vehicle years, makes, models, trims and engines.

Offering people more channels to purchase parts, often at lower prices than the original vehicle manufacturers, provides end customers with greater freedom to fix their vehicles.

Innovation is at the heart of everything we do. Our dedicated engineering teams and visionary leadership are instrumental in developing cutting-edge patented solutions that drive growth in the vehicle aftermarket. With a relentless focus on pushing boundaries and solving challenges, we are proud to lead the way in transforming the industry landscape.

Bringing new replacement parts to the aftermarket quickly and accurately starts with reverse engineering from an original equipment design.

Using industry-leading tools and processes, our team of over 100 engineers set out to develop aftermarket parts that not only match the fit and function of their original counterparts, but also improve them where there are common design failures or service challenges.

Metrology is more than just measurement-it’s the foundation of quality, precision and trust. Accurate measurement systems ensure our products meet the exact standards and performance expectations.

Our commitment to metrology goes beyond compliance—it’s a driving force in how we design, validate, and refine every part. By leveraging advanced measurement techniques, we ensure consistency, durability, and reliability in every component we produce. This focus on precision allows us to anticipate challenges, eliminate variances, and deliver parts that not only meet but exceed customer expectations. Through this dedication, we position metrology as a cornerstone of innovation, giving our customers the confidence that they’re getting the very best every time.

Performs non-destructive inspection of manufactured products by taking multiple X-ray images from different angles to create a detailed, high-resolution 3D model of an object's internal and external structures.

Lumafield X-ray CT scanner

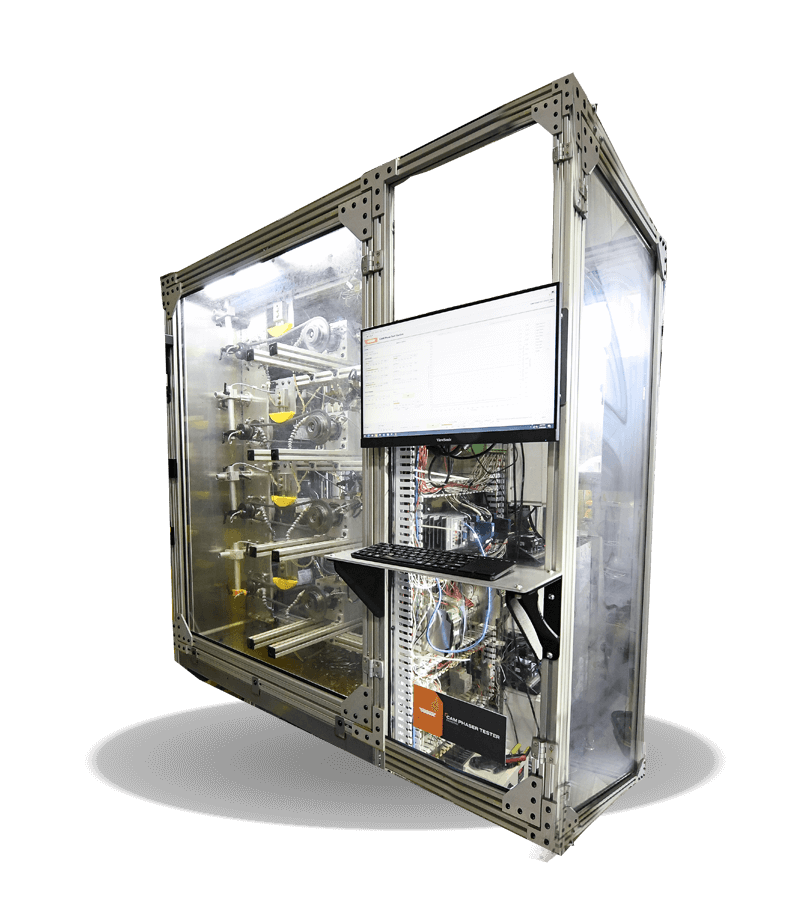

Custom-built and deesigned to help ensure the highest aftermarket quality.

Camshaft Phaser Tester

Measures rubber hardness on small O-rings and gaskets. Often used in conjunction with thermal chambers to perform a “heat age” test, simulating on-engine aging of rubber gaskets.

IRHD Hardness Tester

Because exact replacements are critical to installers, our process begins with capturing every shape and surface detail of the original design with our hand-held 3D scanner. We then scan the part using our coordinate-measuring machine, which allows for precise dimensional analysis and accurate tooling inputs. Building on the data gathered from these scans, our design engineers create a unique digital 3D model.

Creaform Scanner

Because repair professionals need solutions fast, we perform rapid prototyping of new designs in our 3D printing lab to accelerate innovation. Using filament deposition printers, we can quickly generate plastic prototype parts so accurate they can be installed and tested on the vehicle. Prototypes for finer parts such as electrical connectors and other fittings with tight tolerances are printed on our stereolithography apparatus printer.

3D Printer

Projects light across a sample part and magnifies the image using a telecentric lens. Ideal for measuring small machined details, including threads and gears.

Optical Comparator

To further accelerate our speed to market with new solutions, our engineers use powerful computer-aided design software to design and test improvements in a virtual environment. By altering attributes like material type, physical dimensions and other specifications, they can optimize a design using finite element analysis before ever making a real part.

Faro Arm Scanner

Measures material composition using infrared spectrometry.

FTIR Spectrometer

Digital camera measurement system. Magnifies features to allow detailed analysis of gaskets, circuit boards, gears, and other small parts.

Vision System

Production prototypes and manufacturing samples are rigorously tested before our customers ever see a first delivery.

Depending on the type of part, it may undergo tensile strength and hardness testing in our material lab, be subjected to corrosion testing in our salt fog test station, undergo hydrostatic burst testing, be measured for performance under extreme temperatures, or undergo up to a million sequences of life-cycle testing.

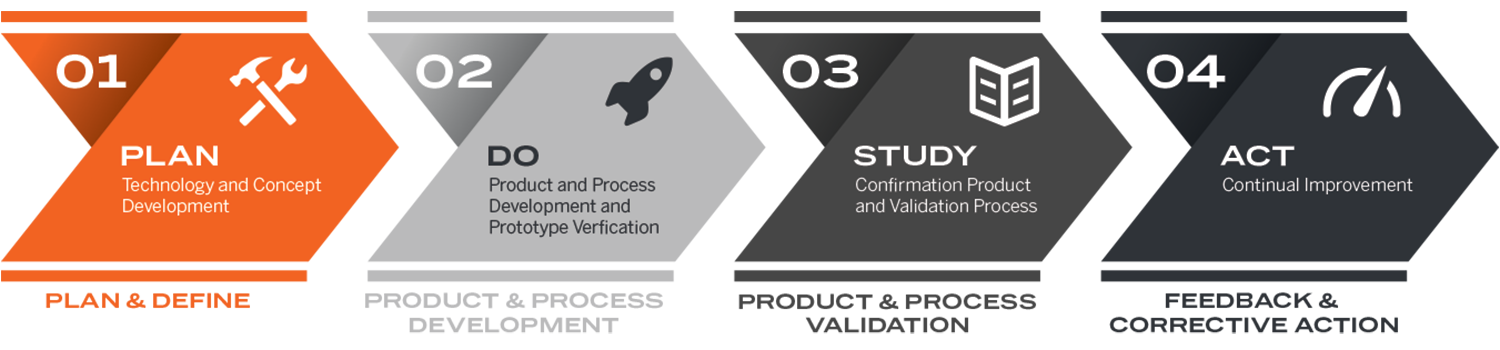

At Dorman, we use the Advanced Product Quality Planning (APQP) framework of procedures and techniques when developing products. This automotive industry standard is also used by Original Equipment Manufacturers and their parts suppliers. Our goal is to support our customers’ success by planning for a quality product from the beginning, and then assess both internal and market feedback to support continual improvement.

We outline clear requirements and objectives to ensure every project begins with precision and purpose.

Our engineering team designs parts that deliver reliability, durability, and OE-level performance. We create robust manufacturing processes that guarantee consistency at scale.

Rigorous testing and validation confirm that both products and processes meet the highest standards.

Continuous monitoring and improvement drive innovation and long-term quality you can trust.

Dorman’s electrical components follow a similarly rigorous engineering process, from decoding original equipment control modules to fully capture their functionality, to assessing printed circuit boards and other physical design features for weaknesses.

Our in-house software team writes and tests entirely new, proprietary software, and if necessary, taking advantage of updated sensors and processors.

To test and validate each part in real vehicles, we have our own advanced testing facility we call The Dorman Proving Grounds Garage.

With state-of-the-industry tools and equipment, this 4,000-sqare-foot controlled environment is an extension of our engineering labs, allowing our ASE-certified technicians to test-fit parts, log data and perform testing on our own schedule.

Look around in this 360-degree, interactive visit to the garage to learn more about all the testing and analysis we do here.

We operate several of our own manufacturing facilities in the United States, where we produce both new electronics like ABS control modules, and new mechanical products like drive shafts. These locations operate at the highest standards, using proprietary testing equipment, to assure incomparable quality.

We also work with a network of advanced manufacturers around the world. We have teams of specialists who routinely visit and validate these partners to ensure they operate to our own high standards, in order to consistently outperform aftermarket competitors.

Go behind the scenes of our Lewisberry, Pennsylvania, manufacturing and remanufacturing facility in the adjacent video.

We operate several facilities in the U.S. where we remanufacture parts as well, taking failed originals and restoring them to like-new performance.

These facilities employ industry-leading, proprietary processes that Dorman’s engineers and developers created to deliver the highest quality restored solutions. In remanufacturing products like a variety of modules like TEHCMs and TIPMs, we are paving the way in these techniques and technologies.

Dorman’s a company of companies. We produce so many parts, across every area of the vehicle, we organize our teams into largely independent specialty groups. This way, we can still deliver quality and concentrate expertise at scale.

Below are our six different product teams. Click on each to learn more about the products they manage.

New and remanufactured modules, clusters, sensors, hybrid batteries and more.

Everything from fans to manifolds, and thermostat housings to throttle bodies.

Automotive technology is evolving rapidly and it shows no signs of slowing down to let the aftermarket catch up. Dorman is keeping pace with new technologies as they emerge, developing solutions in categories that didn’t even exist a decade ago in the aftermarket. At the same time, we’re standing up for the rights of both mechanics and motorists to maintain automobiles independently from the manufacturer.

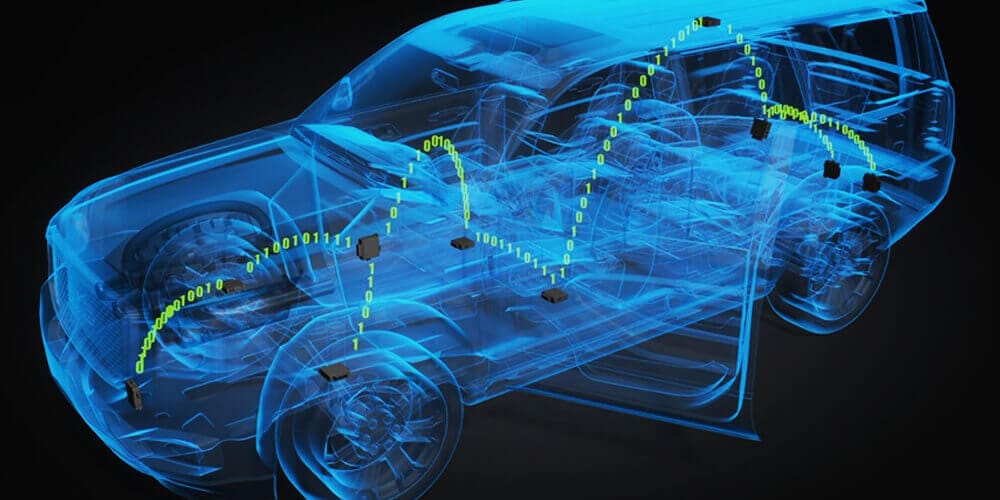

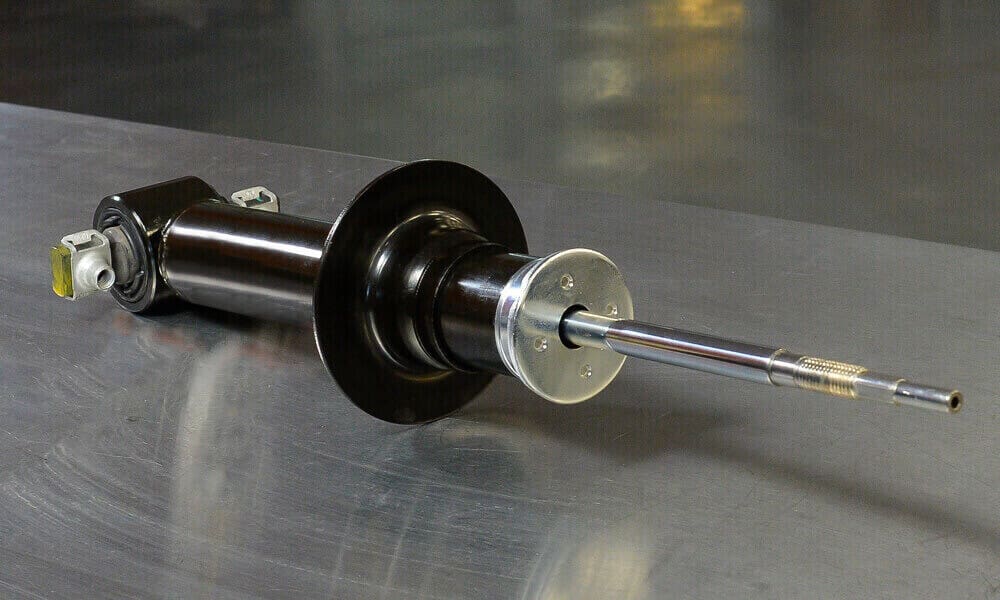

Technologies to increase active vehicle safety continue to work their way from high-end luxury vehicles to the mainstream.

Advanced driver assistance systems like lane-departure and blind-spot monitoring, active cruise control, collision avoidance and reversing cameras depend on accurate sensors, control units and actuators to inform drivers of potential hazards and even take corrective action when they fail to respond.

We are steadily expanding our offering in this area to lead the aftermarket in these new technologies.

As vehicles become increasingly electrified, Dorman is changing to meet new service demands.

We are continuously improving our hybrid battery remanufacturing process to ensure more reliable, longer-lasting power storage for hybrid vehicles in preparation for the coming wave of fully electric cars and trucks.

These vehicles will introduce entirely new systems that don’t rely on a combustion engine at all. Dorman will be ready for a future that includes a mix of combustion, electric and hybrid automobiles.

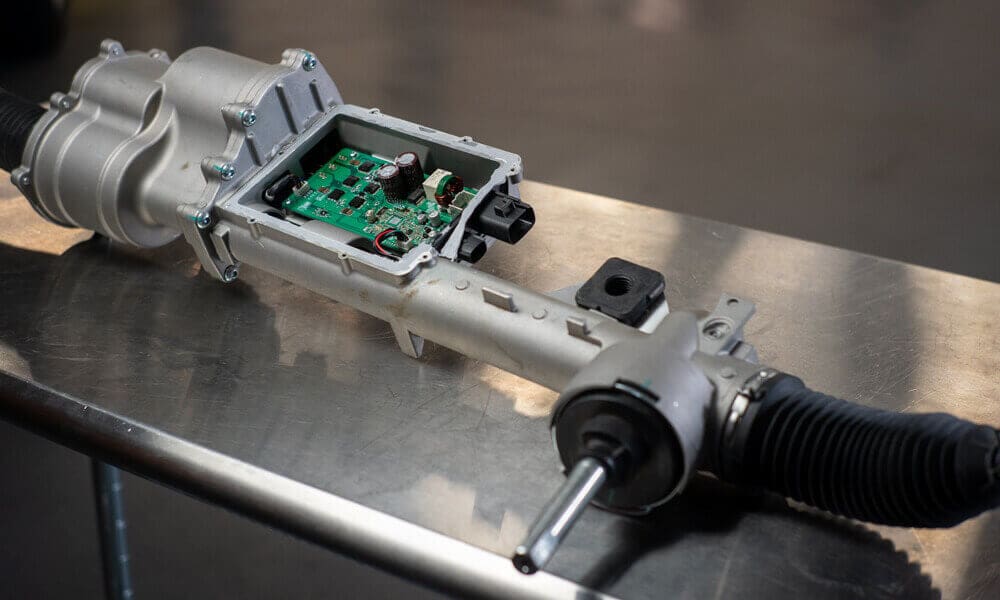

Increasingly, traditional mechanical systems are evolving to include electronic drive and control units. These electromechanical technologies – or mechatronics – increase vehicle efficiency, reduce weight and allow for more compact component packaging.

From electric power-assisted steering (EPAS) to transmission electro-hydraulic control modules (TEHCM), these systems all rely on sensors, actuators, controllers and mechanical components to work properly.

Dorman’s expertise in both complex electronics and mechanical systems keeps us at the leading edge of the aftermarket, and the first to develop new solutions.

Maintaining a thriving auto repair industry in the face of rapid technological change also requires access to high-quality service information. That’s why we have developed and rapidly expanded Dorman Training Center across North America to provide advanced technical training for modern vehicle systems. With both in-person and online classes on topics ranging from properly using scan tools to diagnosing problems with hybrid vehicle systems, our goal is to give repair professionals the skills they need to be prepared for the future.

Fraudulent warranty claims cost our automotive parts industry hundreds of millions of dollars annually. “Check the Part” has been started by industry experts to help address these fraudulent claims by encouraging parts professionals to simply open the box and visually inspect returns.

Dorman supports the Check The Part initiative to prevent fraudulent product returns. Learn more about this campaign here.

Dorman’s mission is to give people freedom to fix their vehicles. That’s why we have developed thousands of products that make motor vehicles easier and less expensive to repair. That’s also why we are passionate and active supporters of the right to repair movement. We are members of the Auto Care Association and other organizations that regularly advocate on behalf of auto repair professionals and motorists, because we believe this issue is critical to the future of a healthy and equitable aftermarket.

Want to ensure consumer choice and safeguard a free and fair repair market? You too can support right to repair legislation. Learn more at RepairAct.com.

Our Body team delivers many of the product categories that first put Dorman on the map.

Categories like door handles and window regulators didn’t exist in the aftermarket until Dorman developed them, allowing shops to stop sending vehicle owners back to the dealership or the scrapyard.

As time has gone on we have continued to deliver new solutions like replacement park assist cameras and liftgate motors to solve more modern vehicle problems.

Our Complex Electronics and Remanufacturing team is at the forefront of innovation as cars and trucks become more technologically advanced.

We manufacture many of our own electronics in the USA as well as remanufacture components using proprietary equipment to deliver high-quality, cost-effective replacements.

This team has pioneered new aftermarket categories like hybrid batteries, ABS control modules, transmission control modules, and many more electronic modules that are critical to operating modern vehicles.

Our Chassis team delivers a wider range of solutions for the foundation of a vehicle than anyone else.

This team introduced quintessential aftermarket categories like control arms, and has expanded to deliver high-performance ball joints, tie rod ends, stabilizer links and hundreds more part types.

But we also go well beyond traditional chassis categories, developing entirely new product lines like advanced active suspension, pre-pressed assemblies and rust-repair kits.

Our Undercar team manages a diverse range of products critical to making a vehicle stop and go, from fuel and transmission lines, to drive shafts and wheels, to brake hoses and brake hardware.

Servicing these systems can often be difficult, but Dorman has constantly introduced innovations that have made maintenance simpler, such as preformed and flexible brake and fuel lines, drive shafts with serviceable U-joints, split brake dust shields that save hours on installation, and much more.

Our Engine and HVAC team delivers an unbelievable range of solutions to keep an engine running properly and make a vehicle environment remain comfortable.

These categories include manifolds and variable valve timing solenoids with multiple patents, radiator fan assemblies with highly advanced software, and a variety of parts with upgraded materials to increase durability in rough underhood conditions.

Our Hardware & Accessories unit is the best reflection of Dorman’s heritage.

For much of our history we specialized in small packaged parts and hardware, and many people today know us best from our HELP! brand of products.

Today our Retail team continues to deliver all the necessary components needed for maintenance and quick fixes.